In

Bulgaria a forgery industrie has developed since the 1960s or earlier.

Large quantities of antique coins have been produced and introduced

into the market. These forgeries include specimens from the Greek and

Roman times. They are either struck silver or gold copies using new

dies or silver and bronze cast coins. The majority of these imitations

in circulation consists of the latter because the casting is a

relatively simple process:

- A master form is produced by pressing a coin into

plastic material which is then allowed to solidify.

- A wax model is made by casting molten wax in the

master form.

- The wax model is embeded in heat proof ceramic

material which is then allowed to dry out.

- The wax is molten out and the final casting form is

ready.

- Molten bronze is cast into the final model.

- The ceramic model is broken away and casting

channels removed.

- The coin is patinated.

The principle permits casting simltaneously several coins

and was even used in antiquity to manufacture blanks. Today it is also

used for casting high temperature turbine blading in extremely

complicated forms and with very high precision.

Identification of cast forgeries is very difficult because the

counterfeit is a copy of a genuine antique coin and shape, as well as,

ikonography are no help. The following two methods are helpful:

- Compare Coins:

Specimens with identical shape and ikonography are forgeries. The

method requires a large database of images to be able to make this

comparison. The virtual collection of coins of the Thracian kings in

these web pages is such a data base and has helped identify forgeries.

- Analyse Material:

Modern electronic analysis techniques permit fast analysis of large

quantities of specimens. The equipment, however, is quite expensive and

not easily accesible. This method has also been used in some cases.

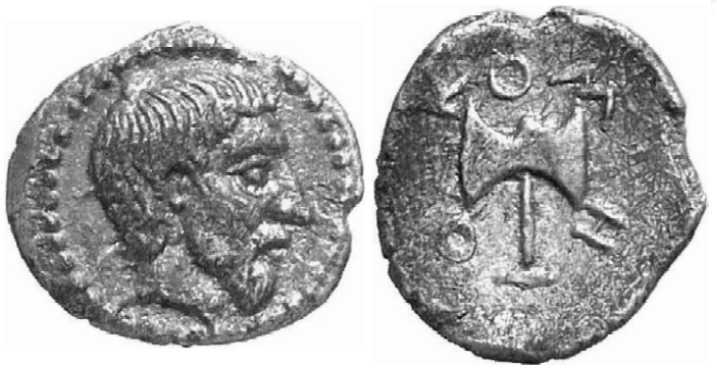

The following coins have been identified by one of these

methods as

modern forgeries.

|