| 450 BC - 400 BC |

Abdera

Thracia

Αβδηρα Θράκη

Αβδηρα Θράκη

| Hemidrachm / Ημίδραχμον AR 12 |

SHH 762 |

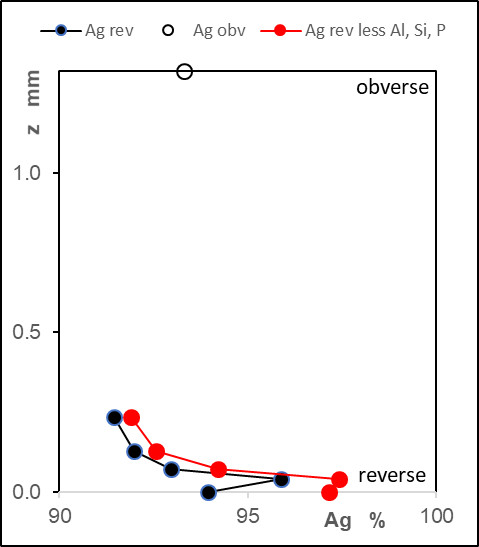

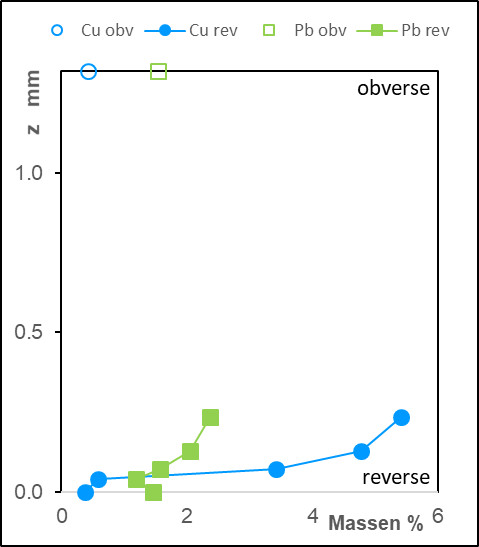

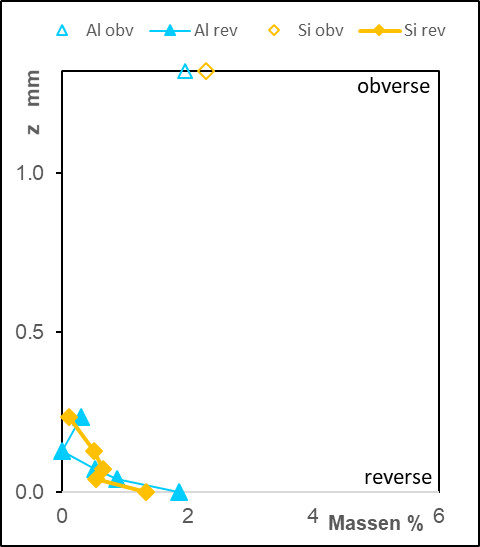

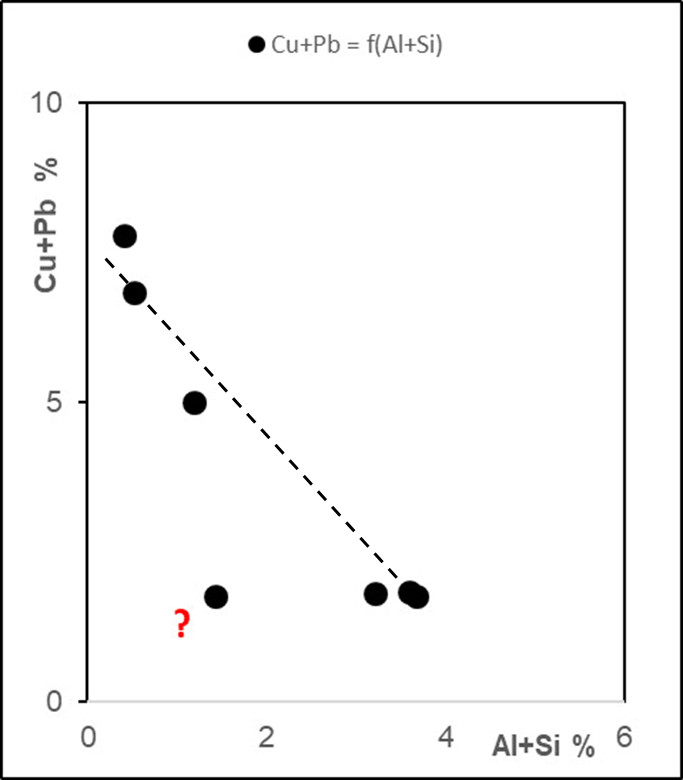

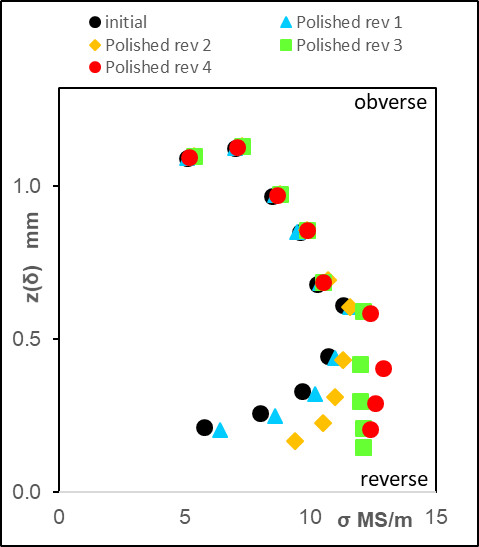

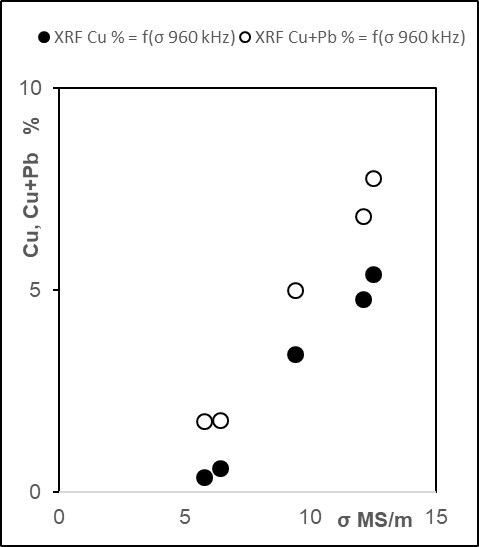

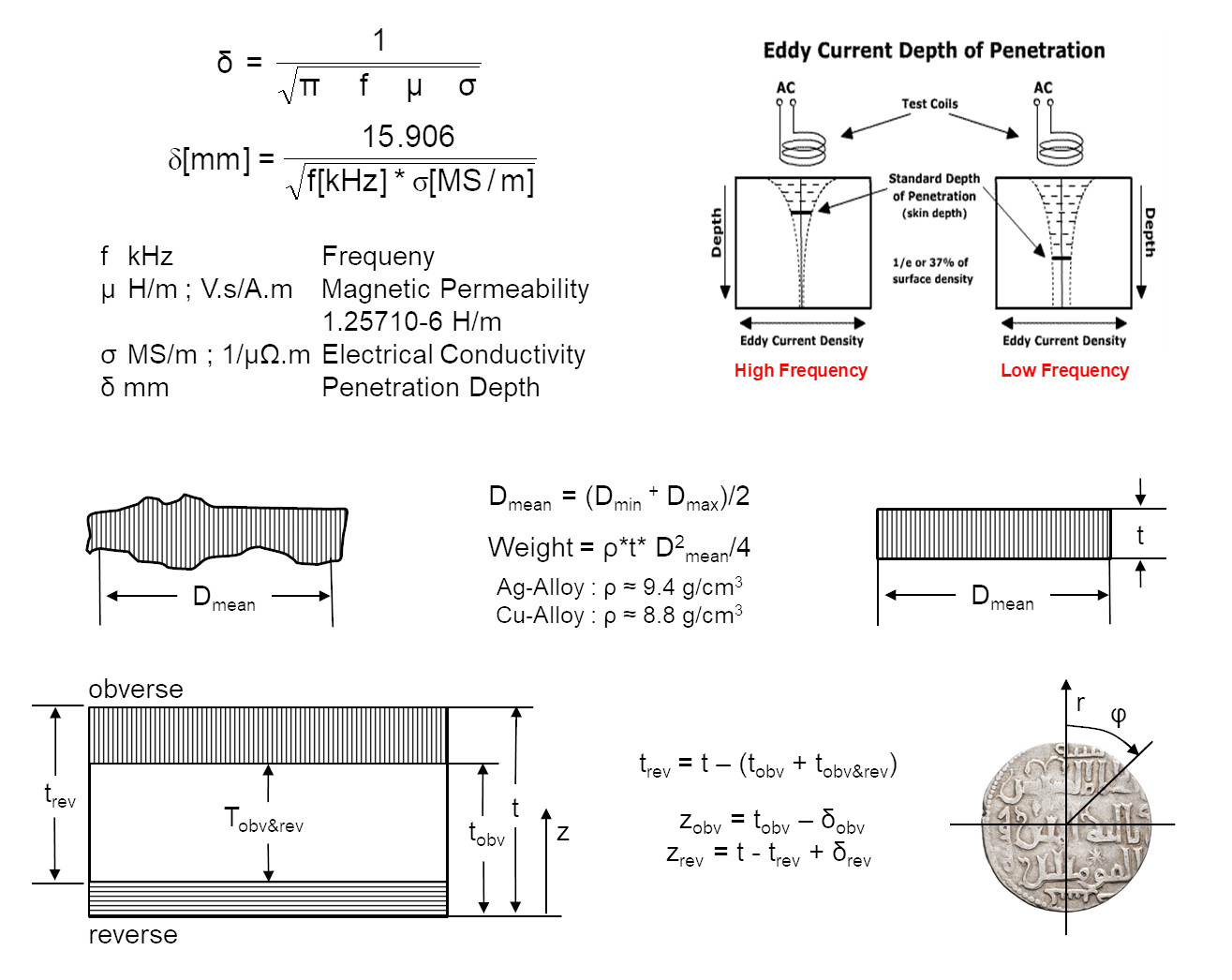

Material Composision Analysis

Definitions |

|

Measurement

coordinates r and φ

are referred to the die orientation of the obverse

Electrical Conductivity σ, SigmaTest, 8

mm sensor,

22.8./24.10.2021

Composition Niton XL2 air plus, 8 mm

Colimator,

23.10./24.10.2021

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Graphic

presentaion of measurement results XRF-Data for Al, Si and P have been included, because they have an effect on electrical conductivity.

|